Screen meshes which can be used are of several materials such as silk, fabric, nylon and even of metal. There is more than estimation numbers of thin cloths used as mesh in screen printing field. Different people think differently while working in screen printing field. Therefore I am writing here the important things especially when you are trying to select some silk mesh for your screen and for your specific work.

Resolution of the Mesh

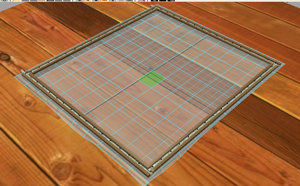

First of all the most important point is to understand the concept of DPS (dots per inch) in screen printing. Although a silk cloth doesn’t have any dots on it, but here, dots mean tiny holes that exist in silk mesh among threads. Or you should say holes per inch. And per inch means per inch square indeed, see the image below,

Holes in silk cloth in per square inch

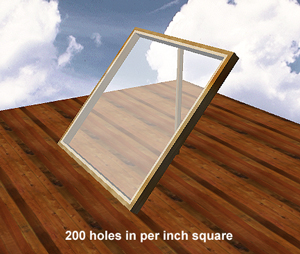

Notable thing is the resolution (holes per inch) of your screen mesh. If you have a little amount of holes in per inch square of silk cloth it means that you have low resolution silk mesh. A low resolution silk mesh can only be used in thick and bold printing. See image below ……………………..

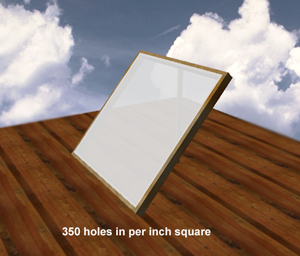

On the other hand a high resolution silk mesh can be used for details in printing. For example you are going to print a half tone photograph on some surface. You will have to use some high resolution mesh. The image below should be printed with high resolution mesh like 120-T or 350 holes per inch square.

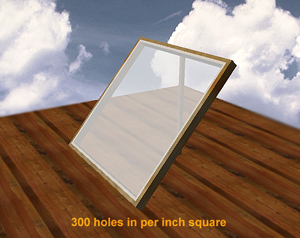

Usually people use low res meshes for textile printing. Low resolution meshes are often considered less than 200 hps (holes per inch) and high res meshes are considered greater than 250 hps.

1. Lowest resolution mesh, almost 100 holes per inch,

2. 200 holes in per inch square,

3. 300 holes in per inch square

4. 350 holes in per inch square,

You can see that meshes have different densities. It means that you pass the pigments from the holes of the mesh with different amounts and pressure. In short or in simple words when you need to print some very high quality graphics you require a high res mesh and vice versa.