The trickiest part of the silkscreen printing procedure due to the figure of variables that can change the exposure for your screen.

After gaining more practice, I realized I had a lot of problems because I kept altering the variables (i.e. different emulsion kinds/brands, using vellum vs. clearness film, changing printers with dissimilar black ink deposits on the my film, changing exposure light sources, artwork that was very comprehensive versus hard areas, changing the ink for new print, changing the substrate, etc). My instruction is to find solid with a solitary process first, after that study as you alter one changeable at a time. The hop-skip-jump technique will only guide to aggravation and lot’s of tired time and equipments. Belief me, I learned screen printing the hard way.

Be tolerant, be attentive and persist! Once you gain the method bellow of screen exposing, your output will remain regular as long as you follow the similar steps and your tools/materials stay together.

There are several traditions to expose a screen for sufficient print. Anyone light source which are containing UV light, among 350 and 420 nanometers can expose your screen. Some screen printers are use sunlight (which happens to have a fair amount of UV light). This article will presuppose you have a bottom-up light source previously built (i.e. home-based exposure unit for screen or professional unit).

Step 1 – In light-safe environment, set your film positive(s) correct side put onto the glass of your exposure unit. The film positives should show accurately as you intend them to be printed (UN reversed). I leant to place my artwork directly in the center and away for the very limits of the exposure plant.

Step 2 – Place your covered screen carefully (which would completely dried) print side down onto the film positives. Be optimistic to middle the film positives, leaving at least 2-3 inches of room approximately the designs. After that, place a part of foam (cut to the inside size of the silkscreen frame) inside the screen frame. If you wish for extra cautious about light flow, you can fit a black tee-shirt over the foam before putting it into the screen. The film positive should be in between the glass and the screen mesh after this work.

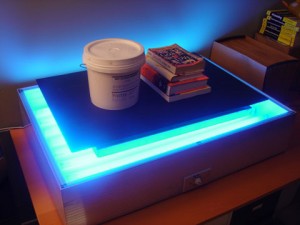

Step 3 – Add some weighted on top of this like (books or something that will distribute a flat amount of force and ensure that the artwork design and emulsion have huge contact with the print box glass.

Step 4 – Turn off all extra lights and after that turn on the exposure box (or if it has a built in timer, set it to the right time limit). Depending on your emulsion thickness, mesh quality, UV tube light wattage and artwork, exposure times might vary. You may have to do this work a few times to determine the correct exposure time. I usually expose for 2 – 3 minutes using this process for sufficient results.

Step 5 – After this work the screen has been exposed, speedily move to the washout area for washing the screen. Use a backyard hose and cold water to spray. Both sides of the screen washout carefully (this stops the chemical reaction). Continue washing the screen with normal pressure. After some time you will see the screen starting to “open up”. One time this happens use the hose to quietly spray the design areas on screen. Regularly washout the screen until all the design has opened up totally. Any time do not employ a pressure washer to do this work because it may really damage parts of the screen emulsion and your stencil.

Step 6 – After this process, clutch the screen to a light in order to observe if the screen still has bits of emulsion that still require to be removed carefully. Once you are satisfied you can leave the silkscreen for drying. This is the detailed work, you may want to be very mild with the washout step and can in fact require less exposure time. In these instances, I would consider drying the screen and then re-exposing to “solidify” the emulsion.

Step 7 – Ready to your printing!